High Speed Fiber Laser Cutting Machine For Metal Sheet With Sheet

Loading System Steel Fabrication

Product Description:

A laser cutting machine is a device that uses a laser beam to cut

materials with high precision and efficiency. Its working principle

is to focus the laser emitted from the laser into a high power

density laser beam through the optical path system. When the laser

beam irradiates the surface of the workpiece, the workpiece will

instantly reach the melting or boiling point, and at the same time,

the high-pressure gas coaxial with the beam will blow away the

melted or vaporized material. As the relative position of the beam

and the workpiece moves, the material will eventually form a slit,

thereby achieving the purpose of cutting.

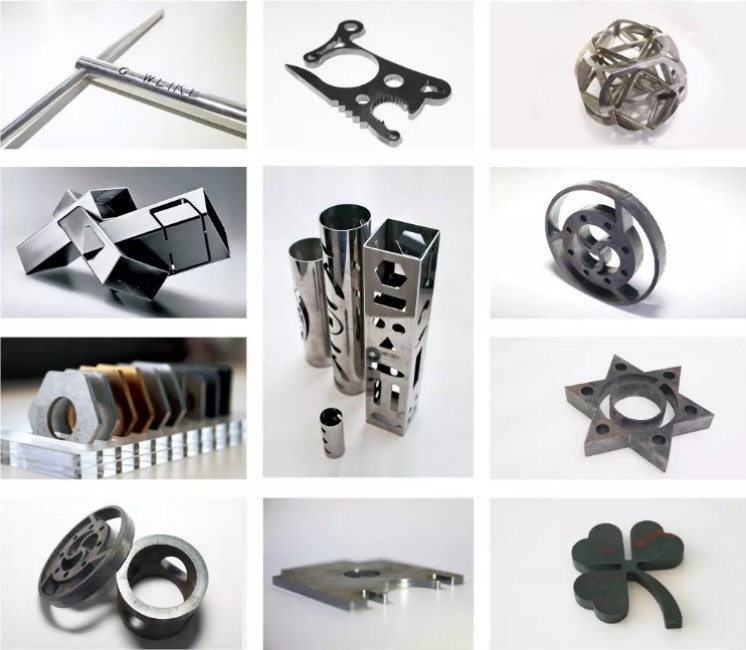

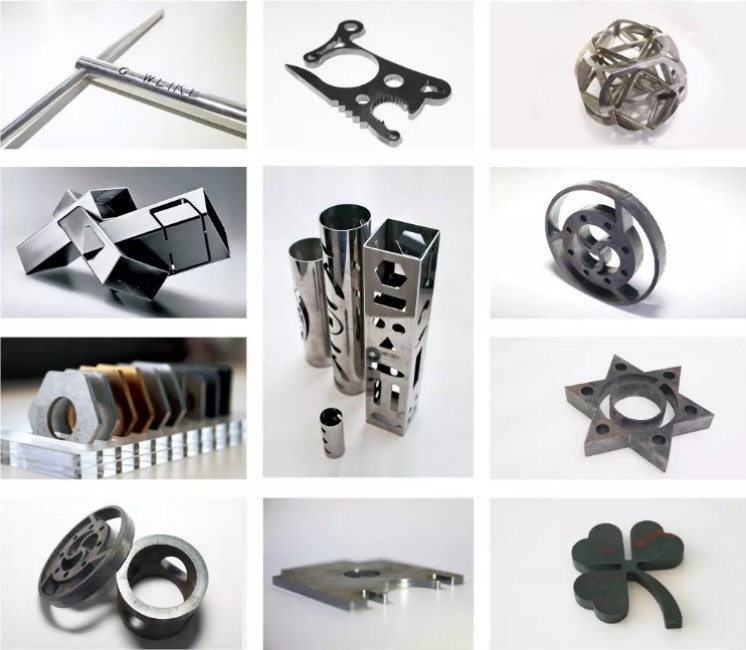

Laser cutting machines have many significant advantages, such as

fast cutting speed, high precision, smooth cuts, and small

heat-affected zones. It is widely used in many fields such as

automobiles, machinery, electricity, hardware, electrical

appliances, medical treatment, clothing, etc. It is especially

suitable for occasions that require high precision, high

efficiency, and complex shape processing. Additionally, laser

cutting machines are suitable for cutting a variety of different

types of materials, including metal, plastic, wood, textiles, and

more.

In general, with its excellent performance and wide range of

applications, laser cutting machines are gradually improving or

replacing traditional cutting process equipment, providing strong

support for modern industrial production.

| Specification |

| Items | Descriptions |

| Application | LASER CUTTING |

| Applicable Materia | Metal |

| Condition | New |

| Laser Type | Fiber Laser |

| Cutting Area | 3000*1500mm |

| Cutting Speed | 120m/min |

| Graphic Format Supported | AL.PLT,DXF,BMP,Dwg |

| CNC or Not | Yes |

| Cooling Mode | WATER COOLING |

| Control Software | Cypcut/Bochu |

| Place of Origin | China |

| Laser Source Brand | MAX/Raycus/IPG |

| Servo Motor Brand | FUJI |

| Guiderail Brand | HIWIN |

| Control System Brand | Cypcut/Bochu |

| Weight (KG) | 2000KG |

| Key Selling Points | High-accuracy |

| Warranty | 2 years |

| Applicable Industries | Building Material Shops,Manufacturing Plant,Machinery Repair

Shops,Construction works,Energy &Mining |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 2 years |

| Core Components | Pressure vessel,Motor,Bearing,Gear,Pump,Engine |

| Products handled | Sheet Meta |

| Feature | Water-cooled |

When choosing a laser cutting machine, you can refer to the

following steps and precautions:

1. **Clear requirements and budget**: First, clarify your

production requirements, including the type of material to be cut,

thickness, cutting accuracy and efficiency. At the same time,

consider your budget range so that you can choose the right

equipment when purchasing.

2. **Understand the market and technology**: Understand the brands

and models of laser cutting machines on the current market, as well

as their performance characteristics and technical parameters. At

the same time, pay attention to the latest developments in laser

cutting technology so that you can purchase equipment with advanced

performance and reliable quality.

3. **Choose the right power and format**: According to the

thickness and format requirements of the cutting material, choose

the right laser power and machine size. Generally speaking, the

thicker the plate, the greater the laser power required; and a

machine with a larger format can improve production efficiency.

4. **Consider cutting accuracy and efficiency**: Cutting accuracy

and efficiency are important indicators for measuring the

performance of a laser cutting machine. Choosing equipment with

high cutting accuracy and efficiency can ensure the quality of the

products produced and reduce production costs.

5. **Pay attention to the quality and stability of the equipment**:

The quality and stability of the equipment directly affect

production efficiency and product quality. Therefore, when

purchasing, you need to pay attention to the quality of the

equipment's structure, materials, control system, and stability and

reliability.

6. **Consider after-sales service and maintenance costs**: Choose a

brand with good after-sales service and technical support to ensure

that problems encountered during use can be solved in a timely

manner. At the same time, understand the maintenance cost of the

equipment so that costs can be controlled in long-term use.

In summary, choosing a laser cutting machine requires comprehensive

consideration of multiple factors, including demand, budget,

technology, power, format, precision, efficiency, quality, and

stability. By carefully comparing and evaluating equipment of

different brands and models, you can choose the laser cutting

machine that best suits your production needs.

Our service including:

1.2 years quality guaranty, the machine with main parts(excluding

the consumables) shall be changed free of charge if there is any

problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you

need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

If you have any questions about our products, please contact me

with no hesitate.